Importance of self propelled reaper binder for harvesting of wheat crop

Authors: ANURAG PATEL1*, RAJKISHOR SINGH1, S.C. MOSES1 AND DUSHYANT SINGH2

* 3679anuragpatel@gmail.com

1Vaugh School of Agricultural Engineering and Technology, SHUATS, Allahabad (U.P.) - 211007

2ICAR-Central Institute of Agricultural Engineering, Bhopal (M.P.) - 462038

Introduction

India is one of the most populated countries in the world today. Cattle population is about 190.9 million numbers. Both grain and fodder are equally important in order to feed its mammoth population of mankind and cattle. Improved agricultural implements are needed/ required to increase the output of farming operations in the country. Harvesting of crop is one of the most labour intensive operations in agriculture. Yet the most prevalent method of harvesting of crops in India is the manual method, which requires high labour inputs but young population do not involve in this activity. It is estimated that harvesting and threshing consume about one third of the total labour requirement of complete crop production system. With the introduction of multiple cropping systems and short duration high yielding varieties, less time is available between harvesting and sowing of the next crop. This demands increase in labour input to complete the harvesting process on time. Harvesting of wheat crop in eastern U.P. is mainly done manually by hand using sickle. Due to shortage of labour harvesting is delayed and some time whole crop is damaged due to weather hazards. The Self propelled reaper binder is a very use full machine to complete the harvesting of wheat timely.

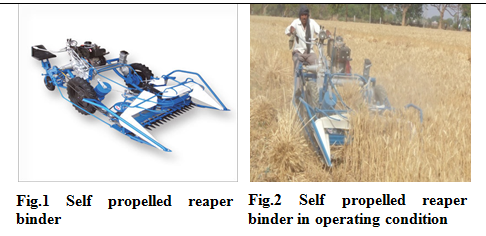

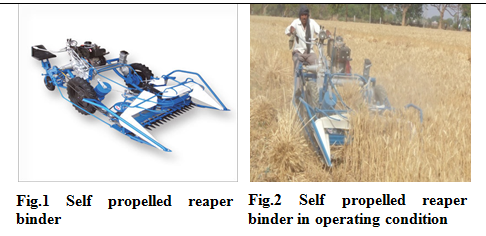

Self propelled reaper binder

It is a suitable for harvesting cereals crops. It has a cutter bar of 1.2 m wide and operated by 10.5 hp diesel engine. Four forward and one reverse gear are provided in the machine. It is steered by hand operated brakes and foot operated pedal for turning left or right. The crop row dividers help the standing crop to enter the machine, by the ‘raising ups’ gently push the crop towards cutter bar and push the crop on to the crop conveying chain. The star wheel keeps the cut crop in upright position towards crop conveyors. The crop is gathered at the knottier mechanism when sufficient quantity of crop is gathered; the bundle is tied and ejected by the ejecting fingers out of machine. An auxiliary conveyer carries the bundle away from the machine on the ground. The bundle size is adjustable with in limit. The machine is shown in fig. 1 & fig. 2.

Features of reaper binder

The self-propelled reaper binder is powered by a 10.5 hp, single cylinder, air cooled diesel engine having rated engine speed of 3300 rpm. It is provided with three pneumatic wheels; two driving wheels in the front having agricultural tread pattern tiers and one steering wheel at the rear having automotive type tire. Other assembly/ sub-assembly are clutch, brakes, steering, and power transmission and operator’s seat available to make the machine riding type. The harvesting system includes consists of crop row dividers, star wheels, standard cutter bar having 76.2 mm pitch of knife section, and wire springs. The effective cutter bar width is 1.2 m; the crop row dividers enter the standing crop and the star. Wheel guide the crop towards the cutter bar and help in slightly lifting the crop after it is cut, and making bundle with help to rope and through the back side of machine.

Table: 1 Specifications of self propelled reaper binder

| S.No. | Particulars | Specification | | 1 |

Make |

BCS | | 2 |

Manufactured by |

BCS-S.P.A. Viale Mazzini, 161 20081 AABBIATEGRASSO, Milano, Italy | | 3 |

Assembled by |

BCS India Pvt. Ltd Vill. Mangarh, Kohara Machiwara road, PO. Kohara, Distt. Ludhiana-141112. | | 4 |

Model |

3LD-450 S | | 5 |

Country of origin |

Italy | | 6 |

Engine |

AIR COOLED single cylinder, (diesel engine) | | 7 |

Power hp/kw |

10.5/8 | | 8 |

CC Capacity, cm3 |

454 | | 9 |

Injection pressure kg/cm2 |

200 | | 10 |

Bore mm |

85 | | 11 |

Stroke mm |

80 | | 12 |

RPM

Low

High |

1150

3000 | | 13 |

Dynamo, amp |

10 | | 14 |

Air cleaner |

Oil both type | | 15 |

Wheels |

Pneumatic tyres | | 16 |

Front |

4.50*19.00 4ply | | 17 |

Rear |

4.00*8.00 4ply | | 18 |

Inflation pressure:

Front kg/cm2

Rear kg/cm2 |

1

1.25 | | 19 |

Wheel treat, mm |

1225 | | 20 |

Wheel base, |

1610 | | 21 |

Working width of cutter bar, mm |

1200 | | 22 |

No. & Spacing of knife guard no/mm |

16/75 | | 23 |

No.& type of knife blade no. |

17, Serrated | | 24 |

Detail of knife drive. |

End of cutter bar is connected with pit man shaft and oscillated by crank | | 25 |

Knife stroke mm |

75 | | 26 |

Stroke per minute (2000 rpm) |

775 | | 27 |

Height of cutter bar mm in transport position, |

260 | | 28 |

Type of crop divider |

Shoe type | | 29 |

Type of crop conveyance |

Gathering forks provided |

Effective field capacity

It is defined as the actual area covered by the implement per hour when the implement is actually working in the field while the theoretical field capacity is the area covered per unit time based on 100 percent of time at 100 percent rated width. It is an important measure of performance of any field implement. On the basis of dates of rated working width and rated speed and the actual width of the reaper recorded during the test in the field, the field capacities were calculated as below:

Effective field capacity = Actual width of cut (m) x speed (km/h) / 10

Theoretical field capacity = Area covered (ha)/time taken (h).

Field efficiency

It is ratio of effective field capacity and the theoretical field capacity. It takes into account the time losses encountered in the field due to various reasons. Field efficiency was calculated as below.

Field Efficiency (%) = Effective field Capacity * 100 / Theoritical field capacity

Cost of operation

The following assumptions were made for calculating the cost of operation of the reaper binder.

Fixed cost

1. Depreciation

It is the loss in the value of capital item due to change in model, wear and tear, breakdown etc. Straight-line method I used to calculated the depreciation as given below.

Depreciation - C - S/LxH

Where C = initial cost of machine

S = salvage value (Rs) = 0.1 C

L = life (years)

H = number of useful working hours. (H/yr)

2. Internet

Internet the investment in a farm is a legitimate cost, since the money spent in buying a machine can’t be used for other productive purposes. The rate of interest (I) was taken as 16 percent/annum as prevalent in the market.

Interest was calculated as shown below.

I = (C + S) x Ir/2x 100 x H

Where Ir = the rate of interest (percent)

3. Taxes, insurance and shelter

Taxes and insurance will not taken into account, as these are not charged on agricultural machinery in India. As it is a small machine it may not require any additional space for shelter.

Total Fixed cost = Depreciation Interest Taxes and Insurance charges.

Variable Costs

1. Fuel cost

Cost of fuel is taken @ as prevalent in the market.

2. Lubrication cost

It was assumed 15 percent of the fuel cost.

3. Repair and maintenance charges

It was taken as 1.5 percent per hours.

4. Labour charges

Considering the working of hours as 8 hours per day. It was taken as follows.

Labour charges-for skilled labour = Rs. 150 per day.

Farmer’s reaction

The reaction of the farmer about the operations of self propelled vertical conveying reaper binder was as follows:

1. The farmer felt that the reaper binder reduces the labour requirement of harvesting.

2. The farmer appreciated the tremendous reduction in the grain losses by using the reaper binder; in comparison to other mechanize harvesting.

3. The farmer appreciated the fact that the use of reaper binder would make the harvesting of crops timely and younger generation will involve in this operation.

4. The farmer complained of the problems in maneuvering of the machine.

Conclusions

The performance of the reaper binder with respect to field capacity, field efficiency, fuel consumption, harvesting losses, labour requirement and cost of operation were studied and compared to manual harvesting method.

1. The operating speed of reaper binder could be varied from 1.9 to 2.55 kmph, working of reaper binder was found to be optimum at the speed of 2.55 kmph.

2. The average operating width of the reaper binder was found to be 94 cm of the rated width.

3. The height of cut varied from 5 to 7 cm, which was acceptable to the farmers.

4. Harvesting of reaper binder grain losses were less as compared to the manual harvesting.

5. The fuel consumption with reaper binder harvesting varied from 1.0 liters per hour to 1.2 liters per hour at different operating speeds.

6. The field capacity of the reaper binder at 2.55 kmph was 0.19 hectare per hour. This means that time required for harvesting one hectare of wheat crop was 5.26 hours.

7. The field efficiency of the reaper binder varied from 70 to 78.5 percent.

8. The cost of harvesting with reaper binder was only Rs. 3000/ha and with manual method, this cost was Rs.6000/ha.

|

References:

1. Devnani, R.S; Pandey, M.M. (1979) Evaluation of field performance of reaper binder for harvesting of wheat crop, Journals of Agril. Engg. Vol. 17: No.1.

2. Hussy, O. (1948) Basic requirements in design and development of self-propelled harvester. Agril. Engg. 2(3): 28-34.

3. Pathak, S. V., Pawar, C.S. and Shirsat, N.A. (2008) Performance evaluation of combine harvester and combination of self propelled vertical conveyor reaper with thresher for wheat harvesting, Ag. Update, Feb-July (2008), Vol. 3 (1&3):123-126.

4. Saran, C. and T.P. Ojha (1967) Design and fabrication of hand operated grain harvester, Unpublished M.Tech. Thesis, IIT Kharagpur.

5. Sexena, B.B. and T.P. Ojha (1985) Determining the effect of harvesting date on yield potential of soyabean. Proceedings of silver jubilee convention. ISAE.83.

About Author / Additional Info: