Authors: RK Sahni1, V Kumar1, SP Kumar1, NS Chandel1, PS Tiwari2

1Scientists, 2Head, Agricultural Mechanization Division

ICAR-Central Institute of Agricultural Engineering, Bhopal

Introduction

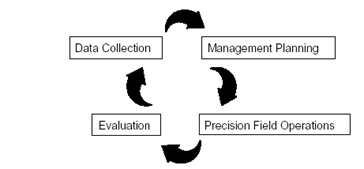

Precision agriculture, precision farming or site-specific management (SSM) is a management system where crop production practices and inputs such as seed, water, fertilizers, herbicides and pesticides are variably applied within a field. Input rates depend on the needs for optimum production at each within-field location. Since over-application and under-application of agrochemicals are both minimized, this strategy has the potential for maximizing profitability and minimizing environmental impacts. Today, low-cost powerful computers, real-time controllers, variable rate application hardware, accurate location systems, and advances in sensor technology have combined to provide the technology to make precision agriculture a reality. The precision farming approach to crop production may be viewed as a four-step process (Fig. 1). An initial step in this process is spatial measurement of those factors that limit or otherwise affect crop production and creation of database. These variability data are then used to develop a management plan for the variable application of inputs such as fertilizers and herbicides. Inputs are applied in precision field operations. Finally, the effectiveness of the precision agriculture system is evaluated with respect to economics and environmental impacts. This evaluation becomes a part of the data collection process for the next cropping season. Multiple iterations through the cycle allow for refinement of the precision management plan in succeeding seasons.

Fig.1. Cyclic nature of the precision farming approach

Why Precision Agriculture?

The potential of using precision agriculture techniques for economic and environmental benefits could be seen through the reduced use of farm inputs such as seeds, water, fertilizers, herbicides and pesticides besides the minimized use of implements in the field. In precision agriculture, instead of managing the whole field based on some hypothetical average condition, which may not exist anywhere in the field, a site-specific differential approach are applied and inputs are applied accordingly. Precision Agriculture offers the possibility to automate and simplify the data collection and analysis and management of information. It allows to take management decisions quickly and implementation on smaller areas within the larger fields.

Advantage of precision agriculture:

- Increases the crop production, quality and productivity in agriculture.

- Dissemination of modern agricultural practices to improve quality, quantity & reduce cost of cultivation by effective uses of agricultural inputs

- Reduction of chemical (Herbicides, pesticides etc.) use

- Efficient utilization of water resources

- Prevents soil degradation in of the field.

- Allows efficient time and input management

- Eco-friendly practices in crop production

Precision Farming Technologies

Global Positioning System (GPS)

Almost all precision agriculture activities now use Global Positioning System (GPS) receivers to provide the spatial coordinates required to generate mapped information. Full availability of the GPS satellite constellation in the early 1990's was a key to enabling the effective measurement of within field spatial variability. The Global Positioning System is a satellite-based radio navigation system developed and operated by the U.S. Department of Defence that allows users to accurately determine their three-dimensional position and velocity anywhere in the world.

GPS provides continuous position information in real time, while in motion. Having precise location information at real time allows soil and crop parameter measurements to be mapped. GPS receivers, either carried to the field or mounted on implements allow users to return to specific locations to sample or treat those areas. GPS receiver with electronic yield monitors generally used to collect yield data across the land in a precise way. Global positioning systems (GPS) are widely available in the agricultural community. Farm uses include: variable rate planting (GPS + variable rate planting system), variable rate fertilizer application (GPS + variable rate controller), field mapping for records and insurance purposes (GPS + mapping software), mapping yields (GPS + combine yield monitor), and parallel swathing (GPS + navigation tool).

Geographic information systems (GIS)

Geographic information systems (GIS) are computer hardware and software that use feature attributes and location data to produce maps. An important function of an agricultural GIS is to store layers of information, such as yields, soil survey maps, remotely sensed data, crop scouting reports and soil nutrient levels. Geographically position data can be shown in the GIS, adding a visual perspective for interpretation. Besides data storage and display, the GIS can be used to evaluate present and alternative management practices by combining and manipulating data layers to produce an analysis of management scenarios. GIS is a very useful tool in developing model to relate various soil, environment and crop parameters to crop yield.

Remote Sensing

Remote sensing is another technology, which holds promise for precision agriculture. A number of researchers and producers are already making use of aerial and satellite images to visualize variability within fields. It is a very useful tool for gathering much information simultaneously. It is the collection of data from a distance using sensors. Sensors can be of hand-held type, mounted on UAV, aircraft or satellite-based. Remotely-sensed data can offer a means for evaluation of crop health condition. Remote sensing technology has been mainly used for identifying crop stand problems and within-season crop stress such as may be caused by water or nutrient deficiency or pest infestation (Frazier et al., 1997). This technology can reveal in-farm variability that affects the crop health and thereby production and can be timely enough to make the adjustment in management practice that increases production and profitability for the current crop.

Yield Mapping/Monitoring Systems

The in-field variation of crop yield is an important input for site-specific decision-making. Crop yield is an integrator of the many varying crop and soil parameters, which are present, such as moisture, nutrients, pest problems, and many others. Linking spatial information on both yield and soil properties through a GIS system can allow for diagnostic determination of the predominant factor(s) controlling crop production. This then becomes the basis for developing precision input strategies. Also, yield measurements can provide feedback on the effect of variable rate application of inputs, allowing refinement of the application plan for future years. Yield sensors have been developed for crops such as potatoes, forage, and hay, but most yield sensing efforts have focused on grain crops. Yield monitors have been available for several years and the major grain combine manufacturers are also offering them as original equipment on their machines. In these systems, the grain leaving the clean grain elevator impacts against an instrumented plate, and the system relates this impact to a grain flow rate. When properly calibrated, yield monitor systems are usually very accurate (<1% to 5% error; Pierce et al., 1997) at determining yield averages over large areas.

Variable Rate Technology (VRT)

The ability to precisely vary application rates while traversing a field is an essential part of precision farming. The variable rate technology (VRT) that makes this possible is probably the best-developed part of the integrated precision farming system.

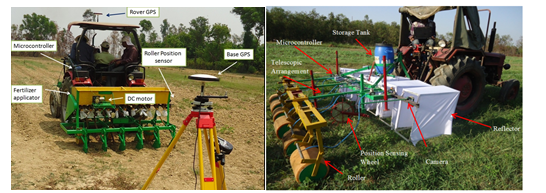

More recently, farm level controllers for VRT fertilizer application and herbicide application have become available. Other developments include VRT irrigation systems and VRT application of animal manures. Control decisions for variable rate application can be implemented either on-line or off-line. In the on-line or sensor-based approach, the controlled equipment incorporates on-board sensors and the sensor data are used immediately for automatic control. In the off-line or map-based approach, data are collected and stored in one operation, and the controlled equipment uses the information in a separate field operation. The map-based approach allows more flexibility in data manipulation and pre-processing but requires that the location of equipment in the field be precisely defined, as with GPS. Most systems currently available are map-based, but more on-line systems will likely become available as real-time sensing technologies become more mature. Hybrid systems, which rely on a combination of both mapped and real-time data, may also come into more widespread use. Traditional uniform N applications, in most cases, result in over and under application of N in various parts of the field due to in-field spatial variability. The ability to variably apply optimum levels of N fertilizer and herbicides corresponding to site-specific field conditions has shown to increase N use efficiency, reduces wastage of herbicides, improve crop yields, crop quality, and net returns while decreasing nutrient overload. The VRT for fertilizer and herbicide application for weed control are shown in Fig.2.

Fig.2. “On-the-go” variable rate application of fertilizers and herbicides (Tewari et al., 2014), Report of AIRCP on FIM, 2015, IIT Kharagpur centre)

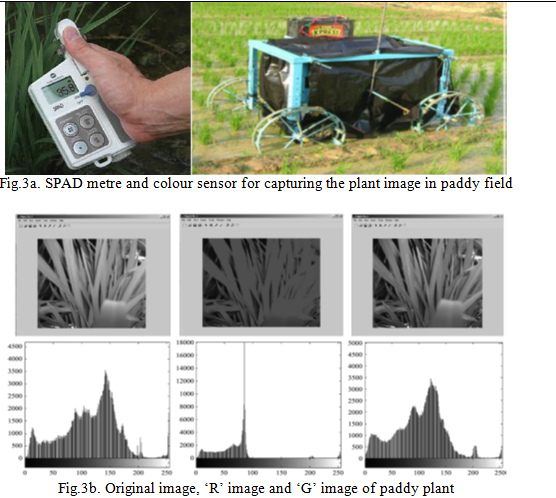

Soil and plant sensors

Sensor technology along with advanced equipment improves the ability for input efficient farming in the environment-friendly way. Sensors can improve on the conventional methods used to derive agronomic recommendations. Compared to the conventional approach, sensors based technology provide rapid and reproducible measurements of soil and plant conditions at field condition, they provide a cheaper alternative that avoids the problems imposed by time-consuming sparse sampling, sample transportation and preparation, and elaborate laboratory analyses. Sensors based technology provides farmers with effective tools for strategic on-farm testing to check conditions at critical stages in the growing season at different locations in their fields. Farmers can use sensed data to build site-specific databases that relate soil nutrient concentrations to plant reaction and crop development during the growing season, and ultimately to yield. Although this might take some time, this approach is more desirable than using the highly generalized generic data of the conventional procedures. Colour sensor is used for images of plant under controlled illumination to predict crop nitrogen content in field. This set up consists of a camera to capture the plant image, four lights to control illumination and a laptop for processing the signal. The results from the test were compared with the chlorophyll content of the crop measured using SPAD meter and the chemical analysis of plant leaf. The processing of the colour of plant image was done using MATLAB 7.0 program. Various features such as R, G, B, normalized ‘r’ and normalized ‘g’ were analysed for both the processes. This showed that the plant nitrogen content can be successfully estimated by its colour image feature. The complete system for estimation of plant nitrogen content using image processing is shown in Fig.3.

Fig.3. Estimation of plant nitrogen content using digital image processing (Tewari et al., 2013)

Precision Irrigation

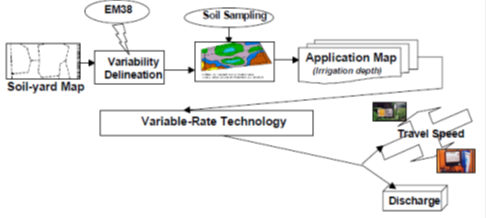

Precision irrigation is sustainable management of water resources which involves the application of water to the crop at the right time, right amount, right place and right manner thereby helping to manage the field variability of water, in turn, increasing the crop productivity and water use efficiency along with the reduction in energy cost on irrigation. Traditional irrigation water management systems utilize a concept of uniform irrigation throughout the field whereas precision irrigation uses a system approach to achieve differential irrigation to crop under field variation (spatial and temporal).

The strategy for precision irrigation application is shown in Fig. 4. The first information needed for delineation of in-field spatial variability originates from the soil-yard maps. The next step is to obtain in-field information (small scale), which may come from utilization of fast, non-destructive real-time sensors, such as EM38, and the concept of surrogated properties, such as EC. This must be followed by soil sampling, based on the maps produced from this sensor, and correlate the surrogate property with the property in question (EC vs. AWC). Map for the management zones within the field (application map) for the field activity, here irrigation, showing the different quantities (depths) and their location within the field is established. Then a decision must be taken concerning the technologies that must be integrated with the present field machinery or need to be introduced, here, variable-rate technologies.

Fig.4. Strategy for precision irrigation application in the field (Al-Karadsheh et al., 2002)

Conclusion

Precision Agriculture provides farmers with the ability to utilize crop inputs more effectively including farm equipment, seeds/seedlings, fertilizers, pesticides and irrigation water. More effective use of inputs means greater crop yield and/or product quality, without polluting the environment. However, it has proven difficult to determine the cost benefits of Precision agriculture management.

References:

1. Al-Karadsheh, E., Sourell, H. and Krause, R. 2002. Precision Irrigation: New strategy irrigation water management. In Proceeding of the Conference on International Agricultural Research for Development, Deutscher Tropentag, Wiltzenhausen. Pp 9-11.

2. Frazier, B.E., Walters, C. S. and Perry, E. M. 1997. Role of remote sensing in site-specific management. The State of Site-Specific Management for Agriculture, pp 149-160.

3. Pierce, F. J., Anderson, N. W., Colvin, T. S., Schueller, J. K., Humburg, D. S. and McLaughlin, N. B. 1997. Yield mapping. The State of Site-Specific Management for Agriculture, pp. 211-244.

4. Tewari, V. K., Arudra, A. K., Kumar, S. P., Pandey, V. and Chandel, N. S. 2013. Estimation of plant nitrogen content using digital image processing. Agric Eng Int: CIGR Journal, Vol. 15, No.2, pp 78-86.

5. Tewari, V. K., Kumar, S. P., Chethan, C. R. and Ekka, U. 2015. All India Coordinated Research Project on Farm implements and Machinery (ICAR) Progress report 2013-2014, 30th workshop, TNAU Coimbatore.

6. Tewari, V. K., Nare, B., Kumar, S. P., Chandel, A. and Tyagi, A. 2014. A six row tractor mounted microprocessor based herbicides applicator for weed control in row. International pest control, Vol.56 (3). Pp 162-165.

About Author / Additional Info:

Working as a scientist at ICAR-Central Institute of Agricultural Engineering, Bhopal.