Authors: PRITI SAHA1, TANMAY HAZRA2

1Dairy Development Officer, Tripura Government,

2Assistant Professor, Kamdhenu University, Gujarat

Thermal processing techniques are well established food preservation and processing. Recently researchers claimed the adverse effect of heat on food quality and nutritional values. So researchers are preferring non thermal food preservation and processing techniques that help to maintain the “freshness” by reducing heat degradation of nutritional and bioactive food components. There are non-thermal food processing techniques available, among which high pressure processing (HPP) is one of the promising technique for food and dairy industries.

What is high pressure processing (HPP) technique?

High pressure processing is an alternate non-thermal food processing method wherein the food is subjected to very high pressure range from 100 – 800 MPa. This technique improves food safety by destroying the bacteria that can cause food borne illness and spoilage. It is a cold processing technique since temperature employed in most of the processing is at ambient range. The foods can be kept for a longer period under better condition.

Principle of HPP -

Under pressure biomolecules obey the “Le-Chatelier” principle i.e. whenever stress is applied to a system in equilibrium, the system will react so as to counteract the applied stress; thus, reactions that result in reduced volume will be triggered under high pressure processing. Such reactions may result in inactivation of microorganisms or enzymes and less adverse effect. There is no adverse effect on nutritional or flavor profile of food.

Advantages of HPP -

1. Thermal degradation of heat sensitive foods can be avoided.

2. High retention of colour, aroma and nutritional value.

3. No re-contamination as treatment is given after final packaging of product.

4. Environmental friendly as no chemicals added.

5. Positive consumer acceptance.

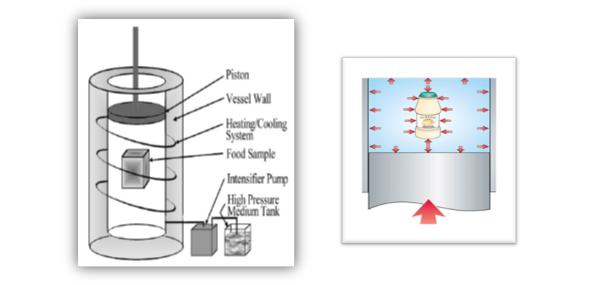

Main components of HPP unit -

It consists of main four parts:

- A high pressure vessel and its closure

- A pressure generating system

- A temperature control device

- A material handling system

Diagram of HPP

Application of high pressure processing technology in dairy industry Recently researchers are applying HPP for preservation and processing of wide range of dairy products including liquid milk.

| Product | Application/Technology/Quality Improvement |

| Liquid Milk | Improved shelf life |

| Sterilized milk | Fresh milk taste and sensory attributes |

| Milk Powder | Reduced Maillard browning |

| Ice cream | Reduction in Ageing time |

| Fat rich products | Ripening, Induced fat crystallization, Improved Whipping ability |

| Yoghurt | Reduced syneresis during storage |

Effects of HPP on physical and chemical properties of milk

- The white colour of milk is due to scattering of light particles by fat globules and casein micelles, HPP treatment leads to disintegration of casein micelles and it decreases the turbidity of milk, results in reduction of whiteness.

- Increase of pH.

- Better emulsion and foaming properties observed in milk.

- Studies show that beneficial effects of HPP of foods are evident only when applied pressure exceeds 400 MPa.

- Vegetative bacterial cells are inactivated by pressures 400-600 MPa.

- About >1000 MPa pressure is required to inactivate bacterial spores. Disadvantages of HPP

1. Very expensive. Capital cost is very high.

2. Non-continuous.

3. Additional heat treatment is required to kill spores.

About Author / Additional Info: